R & D Engineering Design and Prototyping Services

The RTI Engineering Department and machine shop can assist companies needing components or systems to be designed and constructed for a variety of industrial and scientific applications.

Let RTI assist your technical staff in conceptual design to meet your unique process requirements. This extends from simple fixtures to more complex systems.

If necessary, RTI can support lab scale experimentation and testing to arrive at a process and equipment combination that meets the process requirements.

Once the concept is firm, the detailed design can be created collaboratively and the RTI fabrication shop can fabricate the system.

If you’re located in San Diego or the lower California area, check out our San Diego operations.

SolidWorks Documentation

- 3D Modeling

- You Receive Completed Drawings

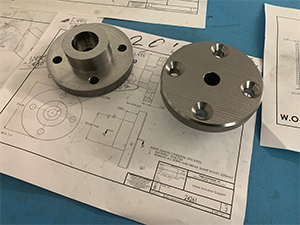

Machining Services

- CNC Milling

- Lathe

- Surface Grinding

Fabricating Services

- Steel and Aluminum Welding

- Welded Structural Frameworks

- 80-20 Framework Assemblies

Examples Include:

Fluid Control

- Dispensing,

- Pumping,

- Spraying,

- Automatic valving and metering.

Temperature Control

- Electric or circulating fluid heating,

- Chilling,

- High temperature processing,

- Data logging.

Motion Control

- Servo motors,

- Hydraulic and pneumatic actuators,

- Ball screws,

- Linear motors.

Machining and Fabrication

- Well equipped machine shop,

- Fabrication shop with steel, stainless steel, and aluminum welding,

- Assembly department for precision devices,

- Electrical assembly for PLC panels.

Mechanical Design

- Vessels,

- Coating processes,

- Web handling (tension, tracking etc),

- Piping,

- Fixtures,

- Brackets,

- Frames,

- Enclosures,

- Interfaces between elements, such as actuators.

Electrical Controls Design

- Process management, such as

- Sequencing of processes,

- Motion,

- Flow rate,

- Pessure and temperature.

- Controls typically include human/machine interface or control panels.

Vacuum and Pressure Systems

- To support thermal sealing,

- Degassing,

- Fluidized beds,

- Fluid management.